Table of Contents

There are several different Pipe Fittings designs, thicknesses, and materials from which to choose for that you should know some basic Information About Pipe Fittings Before Selecting the Right Fittings for your appliances. These Pipe Fittings and flanges are used to join pipes of various lengths and diameters, to provide solid connections. Various materials are used to produce pipes and Pipe Fittings to convey a wide range of liquids and solids. Improper Pipe Fittings can cause a number of issues, including leakages, unwanted flow limitations, and additional expenses.

In HP Pipe Fittings we have Pipe Fittings with a pressure range of up to 1000psi, with a size range of ¼” to 2” and varied as per the requirements, HP Products are produced to meet international quality with optimum prices. We assure you that we will do the very best service in terms of Quality and Prices. We make the Pipe Fittings with tapered threads and straight threads of the Highest quality. In the fittings category, both Pipe Fittings and Tube Fittings are available. We have so many types of Pipe Fittings, so they are capable of use in every application. HP Products are produced to meet international quality with optimum prices. We assure you that we will do the very best service in terms of Quality and Prices. The main features that call for its use are we make the product easy to use, compactness in design, ease of assembly, high reliability, easy availability & global approval.

Pipe Fittings Selection – Tips

Points to consider:

Understand the application and Determine the Product Compatibility:

- The below Information About Pipe Fittings will help you to choose the right fitting type. Choosing the right option plays an essential role in the appropriate working of Pipe Fittings. There are certain liquids that are not suitable with fitting material and these installations trigger leaks or system damages. You need to know certain details before selecting the Pipe Fittings, such as the chemical makeup and the whole range of pressure and temperature during the duration of the valve’s life. Make sure the valve you choose can handle these conditions. Don’t select with guesses or rough estimates. Check the exact product information.

- NOTE: A lot of fittings, curves, or elbows may result in pressure loss and a reduced flow rate.

Check Temperature Level as well as Pressure ratings:

- Suitable temperature levels and also pressure ratings are needed for proper operating conditions. It is necessary to recognize whether the installations are capable of doing at their maximum temperature and also optimum stress rankings since best cannot do both the job all at once.

Make sure the materials are compatible:

- Sometimes some people choose the correct Pipe Fittings but the build material was not correct for some specific applications. There are alternative materials. To know about temperature and pressure ranges, as well as compatibility you should always check the product catalog or you Can Consult Us to choose the right Pipe Fittings for your Application.

Know when to schedule maintenance:

- Every Fitting has a different maintenance schedule. Sometimes manufacturers will hide information about the maintenance cycle. It may be a problem for you later to handle the Fittings maintenance schedule. So check the maintenance detail before selecting the fittings for your application.

Think about the ownership costs:

- A Fittings purchasing price is not its full cost. The purchase price alone does not reflect the full cost of owning, maintaining or replacing that valve over time. You need to know how long a Fittings will run in your specific system between maintenance inspections in order to determine the cost of ownership. Keep in mind that certain Fittings require far less maintenance than others. Others need to be taken off the process line while some may be serviced in place.

Thread Selection Guide(For Threaded Fittings) :

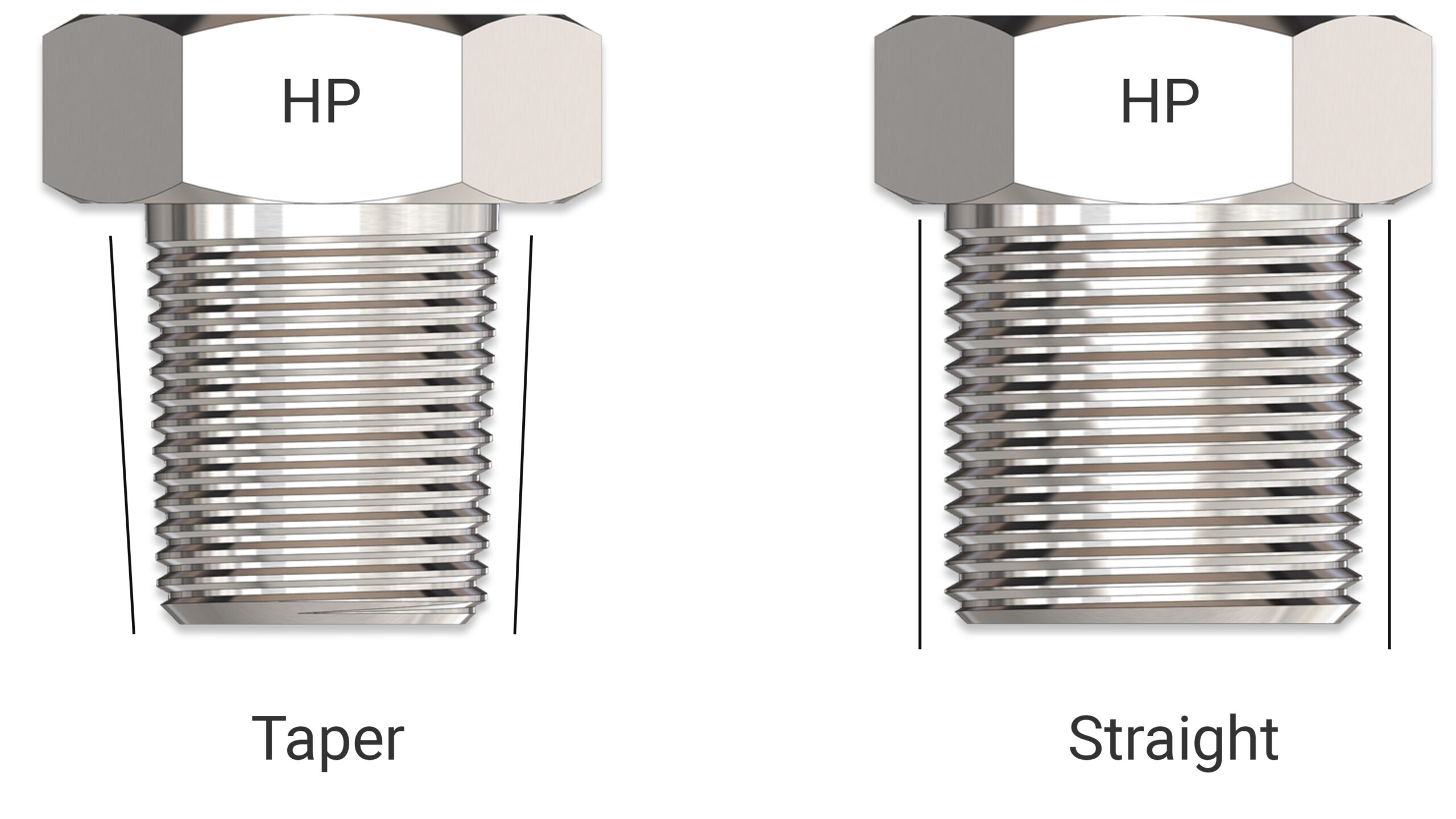

Threaded fittings have screw threads on either their inner or exterior surfaces, to connect pipes with the appropriate threads. Straight threads are those that offer an easy connection but no seal. For fluids or gases tapered threads are made to seal tightly under pressure. A coating or seal tape can be used to increase the dependability of a seal. The term “dry fit” refers to the ability of very accurate threads to seal without the need for extra sealant, which is crucial in situations where the addition of sealant might result in contamination or corrosion. We give below an example of a taper thread and a straight thread. The Image shows a basic construction comparison of taper thread and straight thread

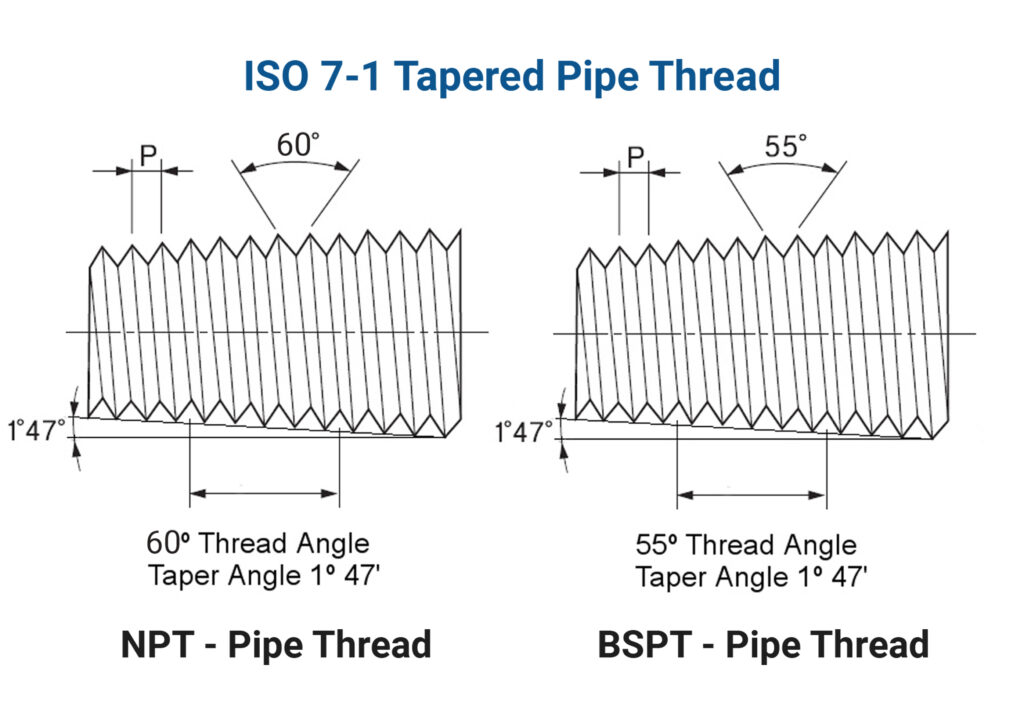

This is a very important consideration for any pipe fitting. All pipes were manufactured with a specification of a standardized outside diameter (OD) and wall thickness which in turn implies that the nominal pipe size is approximately equal to the inside diameter (ID). Nowadays, various thread configurations are used. We give below an example of British National Pipe Tapered Thread(NPT) and Standard Pipe Thread (BSPT). The Image shows a comparison of these two thread styles.

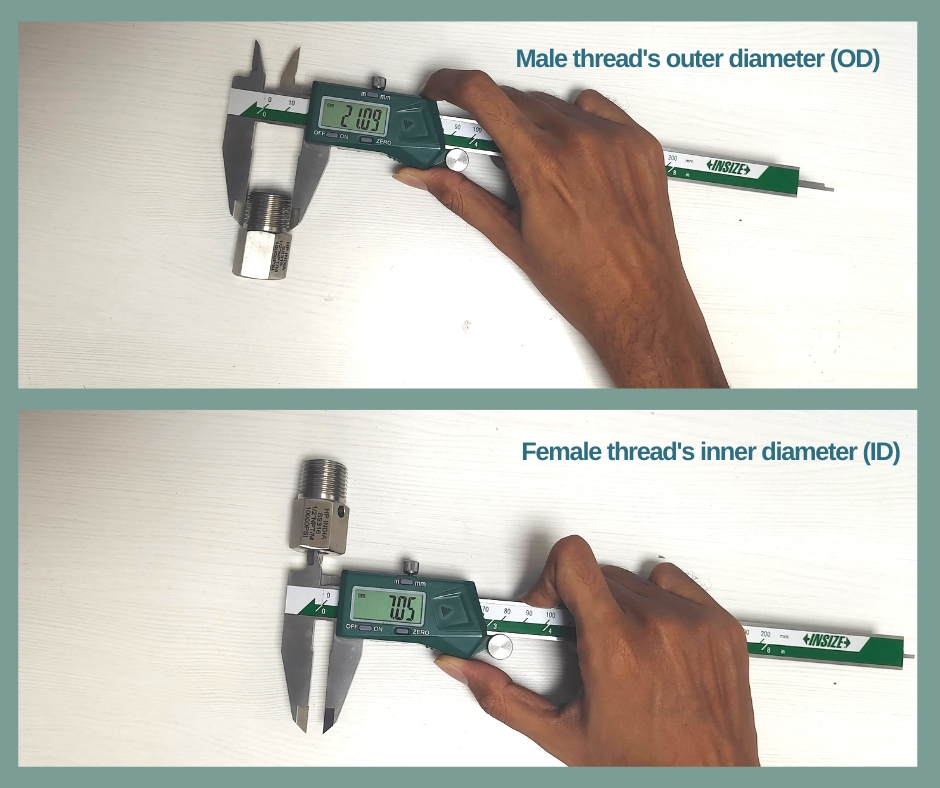

Measuring Pipe Thread:

Since thread dimensions aren’t based on common units of measurement, measuring pipe thread size often causes the most confusion part sometimes. The ID of the pipe determines the thread dimensions. To determine the thread diameter of a male thread or female thread, use a caliper, measuring tape, or ruler. Measure the male thread’s outer diameter (OD) and the female thread’s inner diameter (ID). The below figure will make it easy to understand how to calculate the thread dimension.

Assembling pipe fittings: Tips

- Avoid crossing your threads. if it feels like a fitting is cross-threaded or inserted wrongly don’t force to make it to enter.

- Before using your fittings, clean the ends of them. Debris shouldn’t get tangled up in the threads.

- Avoid overtightening to avoid splitting or cracking the fitting. Particularly when utilizing plastic fittings, this is an issue.

Some easy steps for Buyer while selecting the Product-Tips & Tricks

Before buying pipe fittings, there are a few concerns that need to be addressed regarding the specific pipe fitting in question as well as the manufacturer of that fitting. Here are a few of these queries:

- Is it the required pressure-resistant?

- Is it temperature-tolerant?

- Has its long-term performance been demonstrated?

- How dependable are the joints and seals?

- Can it be correctly fitted?

- Is it confident in the manufacturers?

- Can it tolerate UV radiation and outdoor storage?

- Can it withstand abrasion and punctures?

- Has it received widespread endorsement and acceptance from engineers and inspectors?

- Is it durable and of high quality?

Need More Information? Send your concerns to HP Valves Specialist.

Fill out the form below to start a conversation with our sales and service team. We will arrange for an expert knowledgeable associate to reach out to you within three days to assist you.

No Comments