Certificate /Product Qualification Certification

HP Valves & Fittings had been verified to the requirements of PED (Pressure Equipment Directives) for its Quality Assurance System and for the Fittings & Valves. TUV Nord had awarded HP Valves & Fittings with PED Certificate as per 2014/68/EU, Annex 1, Point 3.1.

HP Valves & Fittings had been verified to the requirements of Welding of Materials for its Quality Management System. TUV Nord had awarded HP Valves & Fittings with Welding Quality Management System Certificate as per DIN EN ISO 3834 Part 3.

Our Double Ferrule Compression Fittings had been qualified based on the successful results of Type test conducted as per IS 15716:2006 for Automotive CNG Sectors and witnessed & certified by ARAI.

Our Double Ferrule Compression Fittings had been qualified based on the successful results of Type test conducted as per ECE R110 & ISO 15500 for Industrial CNG Sectors and witnessed & certified by ARAI.

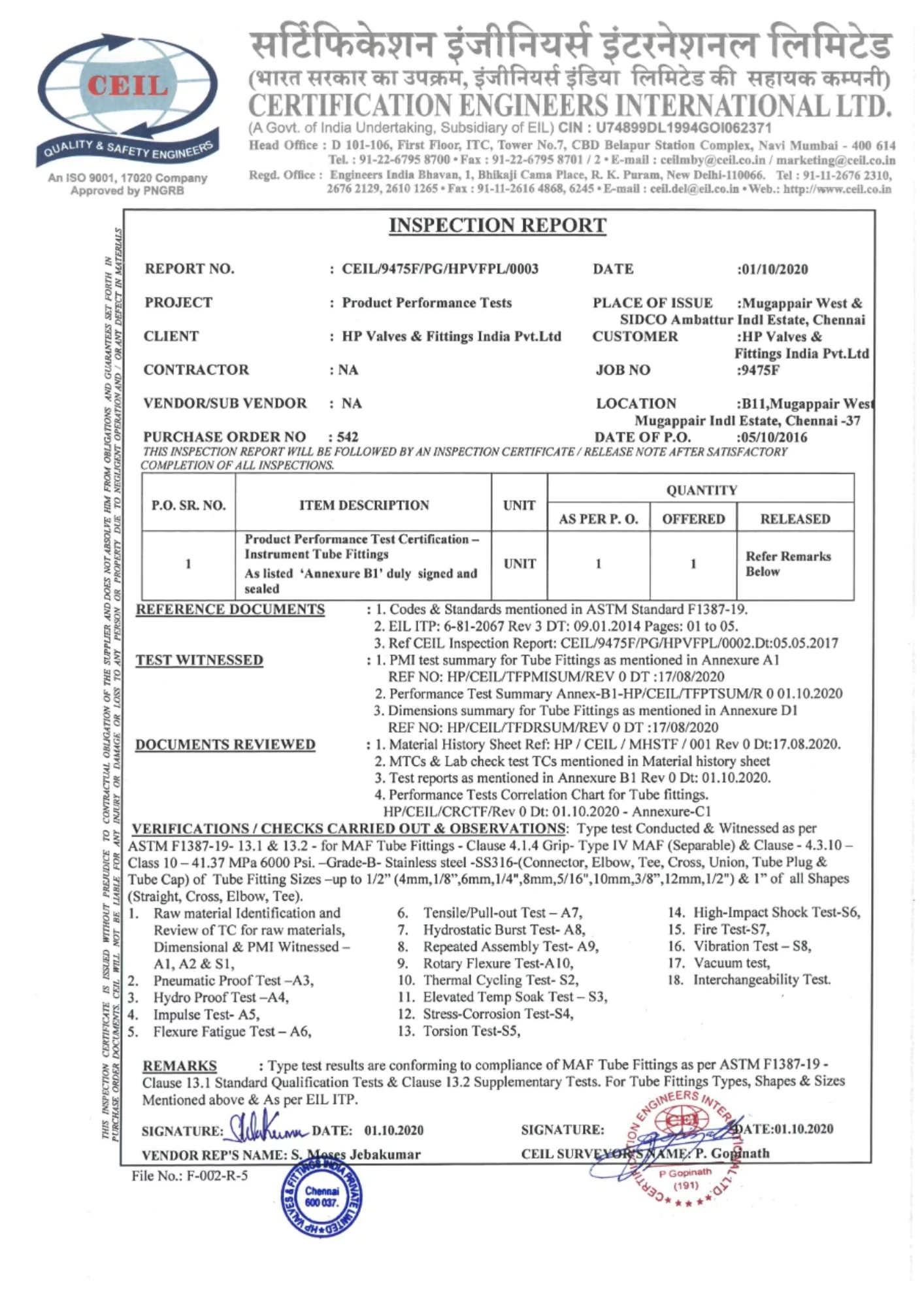

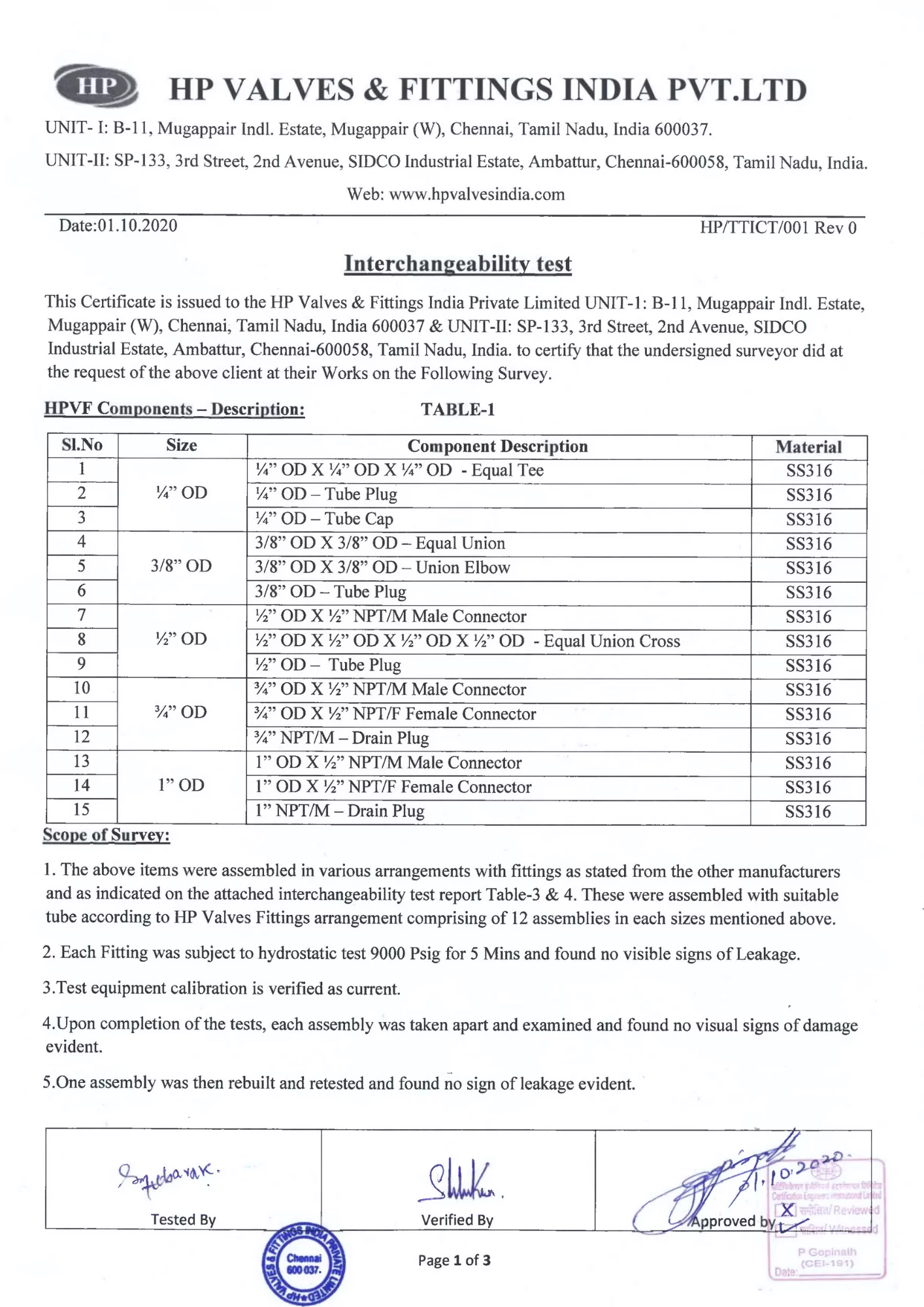

Our Double Ferrule Compression Fittings had been qualified based on the successful results of Type test conducted as per ASTM F1387 2019 and witnessed & certified by CEIL.

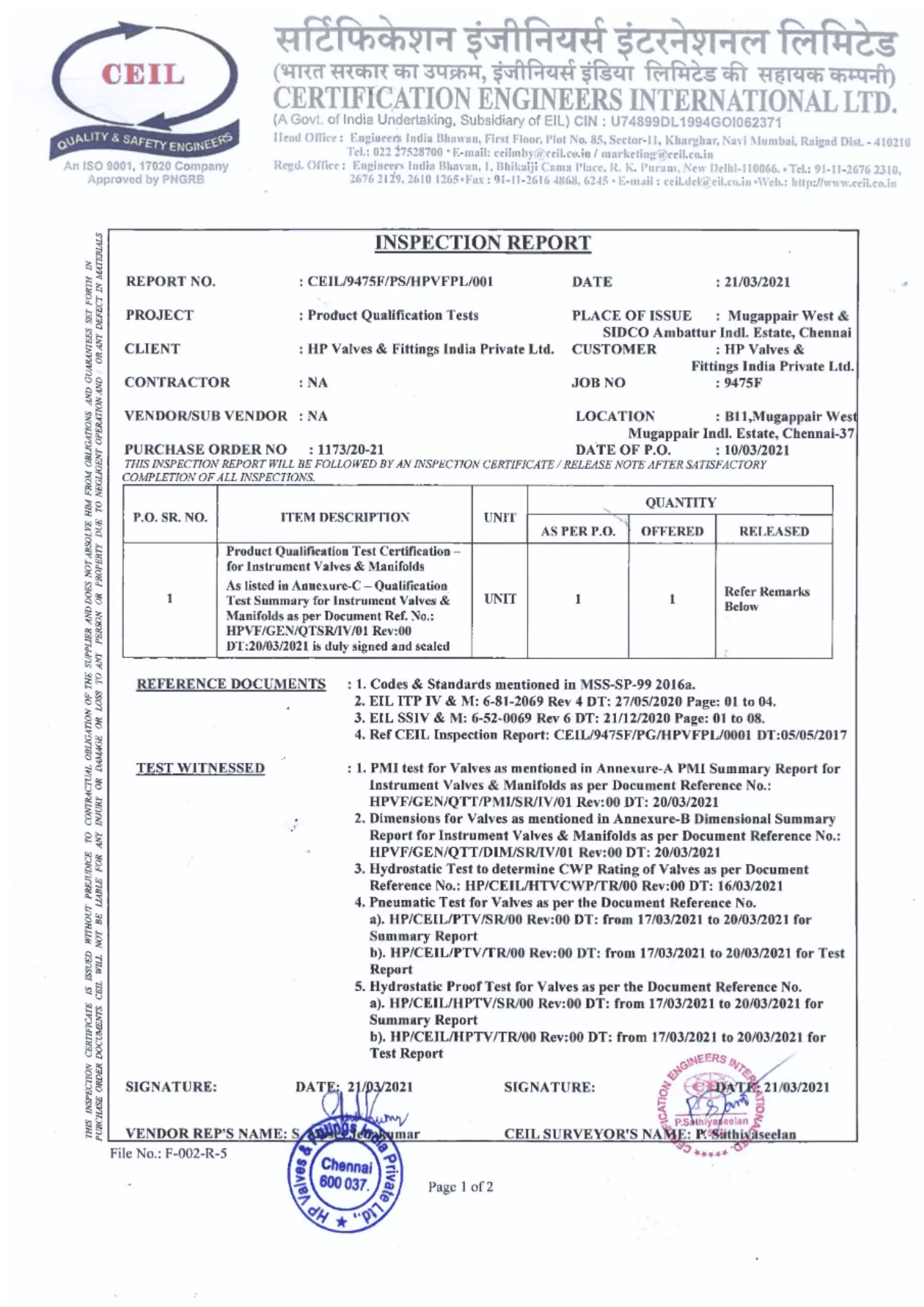

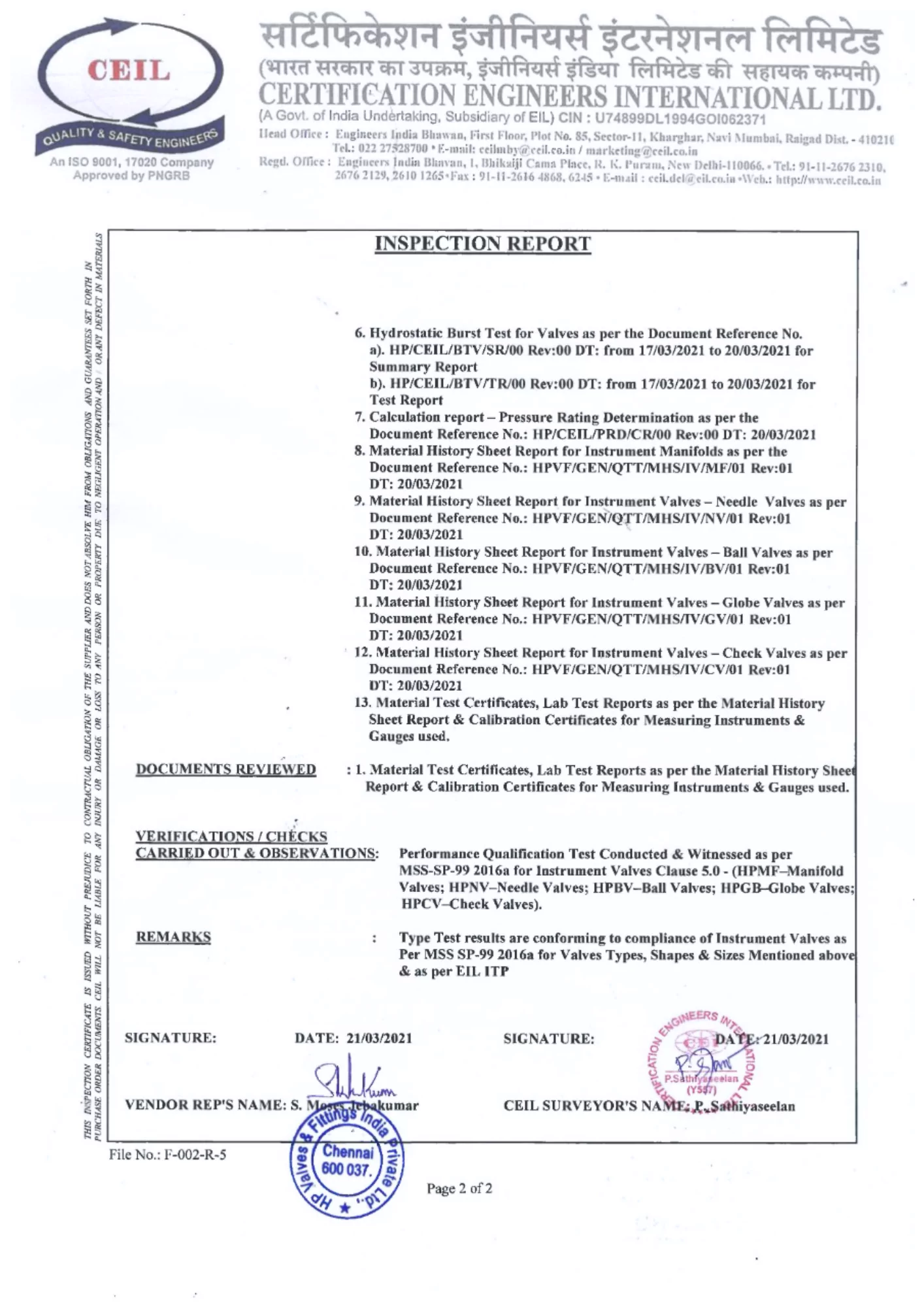

Our Manifold Valves, Needle Valves, Ball Valves, Globe Valves, Check Valves had been qualified based on the successful results of Type test conducted as per MSS SP 99 2016a and witnessed & certified by CEIL.

The Flow Analysis (CFD) are conducted for our Valves and Fittings through In-house Design Applications like ANSYS to meet the customer need.

Our Valves & Fittings are type tested and qualified to the stringent restriction of Fugitive Emission requirements to the International standards like ISO 15848, MESC SPE 77/312.