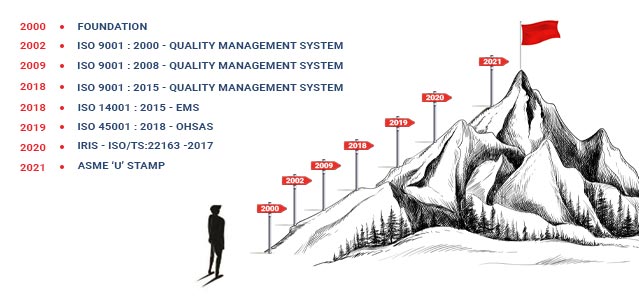

About Us / Our Heritage

COMPANY OVERVIEW

HP VALVES & FITTINGS INDIA PRIVATE LIMITED, was established in the year of 2000 and manufacturing for the past two decades (20 Years). We are one of the leading manufacturers of Instrumentation Valves & Fittings i.e. Tube Compression Fittings, Threaded & Welded Pipe Fittings, Sealant Injection Grease Fittings, Flare End Fittings, Orbital Weld Fittings, Instrument Valve Manifolds, Monoflange Valves, Double Block & Bleed Valves, Needle Valves, Ball Valves, Globe Valves, Check Valves, Gate Valves, Field Instruments such as Air Headers, Condensate Pots, Syphons, Injection Quills, Flanges, Flushing Rings, Thermo-wells, Air Filter Regulators, Pressure Regulators, Instrument Conduit Units (Hook-Ups Accessories) and Custom Build/Specialized Engineering Components in Chennai, India with fully automated manufacturing, advanced in-house testing facilities and R&D under one roof, functioning for the last two decades, meeting International standards and codes for our range of products.

Our Brand Names: HPLOK / HP / HP INDIA / HP VALVES & FITTINGS

PRODUCT CERTIFICATIONS DETAILS

We are Integrated Management System (IMS) Certified Company (ISO 9001:2015, ISO 14001:2015 & ISO 45001:2018) by TUV Nord Group for the scope of Design, Manufacture and Supply of Instrumentation Valves & Manifolds, Fittings and Sealant Injection Grease Fittings.

We are IRIS (ISO TS 22163:2017) Certified Company - We are the first Indian Double Ferrule Fittings manufacturer to obtain this certificate.

Our Products have been certified for ASME ‘U’ Designation as per ASME SEC VIII Div.1 by ASME for the product of Pressure Vessels like condensate pots, Flash drums, Oxygen Concentrators, Sampling pots and other Pressure Vessels

Our Products have been certified for Type Test as per ASTM F1387-2019 by CEIL (TPI Party) for the product of Tube Fittings (Ferrule Compression).

Our Products have been certified for Type Test as per MSS SP-99-2016a by CEIL (TPI Party) for the product of Instrument Valves & Manifold Valves such as Needle Valves / Ball Valves / Globe Valves / Check Valves / Manifold Valves.

Our Products have been Flow Analysis (3D) through HexMesh for the product of Needle Valves / Ball Valves / Globe Valves.

Our product of Needle Valve have been tested as per Standard of ANSI/ISA 75 02.01-2008 “Control Valve Capacity Test Procedure” by FCRI (A Govt. of India R&D Organisation).

Our products have been tested the Fugitive Emission as per Standard of ISO 15848-1 for the product of Needle Valves / Ball Valves / Globe Valves / Manifold Valves / Gate Valves.

BUSINESS SECTORS

Railways Industries

Aviation & Space Industries

Defence Industries

Automotive Industries

Pharmaceutical Industries

Medical Instruments Industries

Laboratory

Railways Industries

Aviation & Space Industries

Defence Industries

Automotive Industries

Pharmaceutical Industries

Medical Instruments Industries

Laboratory

FACILITIES

Build Area – 46,500 Sq.ft.

Total Employees – 200 Persons

Auto Cad LT 2022 – 6 Licenses

Solidworks Standard 2020 – 5 Licenses

Industry 4.0 Shop Floor Digitization

Subject Matter Experts.

Latest Modern Machineries.

In-House Research & Development Centre.

In-House state of the art lab facility.

In-House Sophisticated Testing

Facilities like Low Emission Test,

Vacuum Test, Cryogenic Test,

High Pressure Hydro Test,

High Pressure Pneumatic Test &

High Pressure Gas Test.

WHY HP?

Our Performance Meets your Expectations

Focus on Consistent quality compliance

Follow International codes & standards which ensures

Recognition in the market

Competitive cost effectiveness

Continuous on our R&D Process

Flexibility in design

Quality and traceability on our products.

Fully computerized inventory system

Stringent quality control checks

Timely delivery & Product durability

Service 24 x 7

Customized solutions

Dedicated Professional and expert workforce

CONTINUOUS IMPROVEMENT

Since 2000 HP has capitalized of the importance of continuous improvement and introduced the concept of lean Manufacturing within the company. Under the leadership and guidance of our senior management who have encouraged everyone in HP to participate in all Kaizen events, this has proved to be a great success. HP is continually improving their technical capabilities, product quality and lead time by learning from these events and practices.